storagearts.com

storagearts.com Introduction: Building Your Own Insulated 200+ Storage Shed Tired of flimsy, uninsulated storage sheds that can't protect your belongings from the elements? Building your own insulated 200+ cubic foot storage shed is a rewarding project that provides secure, climate-controlled storage space. This guide will walk you through the process step-by-step, empowering you to create a durable and functional shed tailored to your specific needs. Before you begin, make sure to check local building codes and obtain any necessary permits. Safety is paramount, so always wear appropriate protective gear during construction.

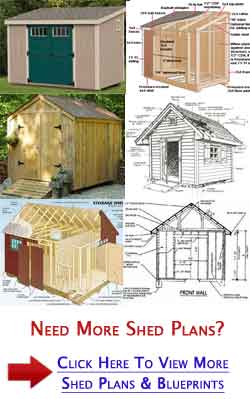

Step 1: Planning and Design First, you need to design your shed. Consider: Size: A 200+ cubic foot shed can range from a small 4x6 to a more spacious 6x8. Measure your available space and determine the ideal footprint. Foundation: Choose between a gravel pad, concrete slab, or wooden skid foundation. A concrete slab is generally the most durable and stable option, but requires more effort to install. A gravel pad offers good drainage and is easier to install, while wooden skids offer portability, but are less durable. Framing: Decide on your framing method stick framing or prefabricated panels. Stick framing allows for more customization, while prefabricated panels are faster to assemble. This guide assumes stick framing. Door and Window Placement: Plan the placement of the door and windows for optimal access and natural light. Materials: Select your building materials, including lumber, sheathing, insulation, roofing, and siding. Pressure-treated lumber is essential for the foundation and any ground contact. Create a detailed plan with dimensions, material lists, and cut lists to ensure accuracy and minimize waste.

Step 2: Building the Foundation Depending on your chosen foundation: Gravel Pad: Excavate the area to a depth of about 6 inches. Compact the soil, then add layers of gravel, compacting each layer. Ensure the pad is level. Concrete Slab: Form the slab using wooden forms. Pour concrete and level it with a screed. Allow the concrete to cure completely before proceeding. Wooden Skid Foundation: Construct a rectangular frame using pressure-treated lumber. Ensure the frame is square and level. Attach additional skids underneath for support. The foundation must be perfectly level to ensure the shed's structural integrity.

Step 3: Framing the Walls Cut the lumber according to your plan's cut list. Construct the wall frames by assembling studs, top plates, and bottom plates. Space the studs 16 inches on center (OC) for optimal strength. Ensure the wall frames are square and securely fastened with nails or screws. Frame the door and window openings according to your plan. Include headers above the openings for support. Raise the wall frames and attach them to the foundation. Use temporary bracing to keep the walls plumb until they are sheathed. Ensure the walls are properly aligned and securely fastened to the foundation and each other.

Step 4: Installing Sheathing and Roofing Attach sheathing (plywood or OSB) to the exterior walls. Ensure the sheathing is properly aligned and securely fastened with nails or screws. Install the roof rafters or trusses according to your plan. Ensure they are properly spaced and securely fastened to the top plates. Attach sheathing to the roof rafters. Apply roofing felt or underlayment to protect the sheathing from moisture. Install the roofing material of your choice (shingles, metal, etc.). Follow the manufacturer's instructions for proper installation.

Step 5: Insulation Install insulation between the wall studs and roof rafters. You can use fiberglass batts, rigid foam boards, or spray foam insulation. Ensure the insulation is properly fitted and fills the cavities completely to maximize its effectiveness. Cover the insulation with a vapor barrier to prevent moisture from condensing within the walls and roof.

Step 6: Installing Siding, Door, and Windows Install the siding of your choice (wood, vinyl, metal, etc.) according to the manufacturer's instructions. Overlap the siding properly to prevent water penetration. Install the door and windows according to the manufacturer's instructions. Ensure they are properly sealed to prevent drafts and water leaks.

Step 7: Interior Finishing (Optional) You can customize the interior of your shed to suit your needs. Install interior walls or partitions to create separate storage areas. Add shelving, cabinets, or workbenches for organization and functionality. Install electrical wiring and lighting if desired. This should be done by a qualified electrician.

Conclusion: Enjoy Your New Insulated Storage Shed Congratulations! You have successfully built your own insulated 200+ cubic foot storage shed. This durable and climate-controlled space will provide years of reliable storage for your belongings. Remember to regularly inspect your shed for any signs of damage or wear and tear and perform necessary maintenance to keep it in good condition. Enjoy the added storage space and the peace of mind that comes with knowing your items are protected from the elements.

Insulated Storage Sheds: Keep Your Valuables Safe And Protected

storagearts.com

storagearts.com Insulated Storage Sheds: Keep Your Valuables Safe And Protected

storagearts.com

storagearts.com Insulated Storage Sheds: Keep Your Valuables Safe And Protected

storagearts.com

storagearts.com

0 komentar:

Posting Komentar